Corrosion, the relentless enemy of metal, is far more than just an unsightly brown stain on an old car. It's a silent, pervasive threat that costs industries worldwide an astronomical sum, estimated to be around US$2.5 trillion annually, equivalent to 3.4% of the global GDP in 2013. From power generation plants and oil pipelines to bridges and manufacturing equipment, the degradation of materials due to corrosion can lead to catastrophic failures, making the early detection and management of this issue critical. Traditionally, assessing corrosion has been a painstaking, often subjective process, relying heavily on human inspection and time-consuming laboratory tests. But what if we could teach computers to see and understand corrosion as well as, or even better than, a human expert?

This is precisely the challenge a team of researchers from the Indian Institute of Science (IISc) has tackled. They have developed an innovative unsupervised machine learning approach that promises to significantly improve how we monitor and manage one of industry's most expensive problems. The team developed an automated system that uses optical microscopy (OM) images to detect and classify the severity of under-deposit corrosion (UDC).

They found that by analysing two key features from these images —the local porosity (the number of tiny holes present in the corroded material) and the thickness of the deposit layer — their system could accurately determine the corrosion stage. Specifically, their thickness-based approach achieved an accuracy of approximately 73% in classifying the corrosion stage in UDC. This represents a significant leap forward, as it provides a quantitative and objective method for assessing corrosion, moving beyond the often-subjective manual methods. They also discovered a clear relationship between these physical characteristics and the underlying chemical conditions: as the deposit thickness increased, so did the concentration of corrosive chlorides. This led to a decrease in pH, indicating a more aggressive corrosive environment. This direct link between visual evidence and chemical severity is crucial for understanding how corrosion progresses.

Did you know, corrosion is a huge money drain? Globally, it's estimated that corrosion costs industries over $2.5 trillion every year, which is about 3.4% of the world's Gross Domestic Product (GDP)! Imagine all the things that money could be spent on instead. |

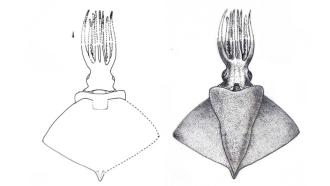

The researchers trained a computer to break down images of a corroded material and identify specific patterns. First, they employed a technique called k-means clustering, a type of unsupervised machine learning. Think of it like a smart sorting algorithm that groups similar pixels together without being told beforehand what those groups represent. In this case, it helped distinguish between the metal, the deposit, and the pores (tiny holes) within the corroded material.

Once the pores were identified, the system then calculated the local porosity – essentially, the number of pores present in a small, defined area (a 5 µm by 5 µm neighbourhood). Simultaneously, it measured the deposit thickness in micrometres (µm). These two measurements became the crucial data points. The researchers then correlated these measurements with known stages of under-deposit corrosion, which are typically classified into four stages based on visual characteristics like the presence of a protective layer, porous layers, or multilayered, fractured corrosion products, by analysing 48 real-world optical microscopy images from steam generators that had experienced UDC, the algorithm learned to associate specific porosity and thickness values with each corrosion stage. The beauty of unsupervised learning is that it doesn't need pre-labelled data (where a human has already told the computer what each image shows), which is a considerable advantage in fields of science where such labelled datasets are often scarce and difficult to create.

The study improves upon traditional corrosion analysis, which often involves time-consuming manual inspections and subjective interpretations that can vary from one expert to another. Supervised machine learning, while powerful, requires large, carefully labelled datasets, which are hard to come by in corrosion studies and can lead to models that only work well for the specific data they were trained on (a problem called overfitting). By employing an unsupervised approach, this new method overcomes these limitations, providing a more robust, scalable, and objective means of assessing corrosion. It automates a process that was previously very labour-intensive, making it much more practical for widespread industrial use. While the 73% accuracy is promising, the researchers acknowledge that future work will focus on improving its robustness, especially for more complex corrosion patterns.

By providing an automated, objective, and scalable method for assessing corrosion, this research directly contributes to improved predictive maintenance strategies across critical infrastructures. This early detection can prevent costly equipment failures, reduce downtime, and enhance safety for workers and the public. It means less unexpected repairs, longer lifespan for vital equipment, and ultimately, a significant reduction in the multi-trillion-dollar economic burden that corrosion imposes globally.

This article was written with the help of generative AI and edited by an editor at Research Matters.